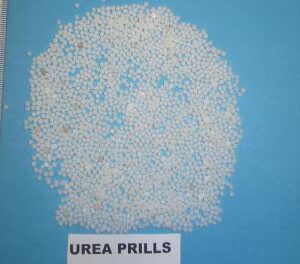

EPS Raw Material

EPS is an abbreviation for Expanded Polystyrene. The raw material used for EPS are small polystyrene beads that have been allowed to absorb 4-7 % pentane gas. The pentane gas is what makes the material expand when heated. EPS can expand up to 50 times the original size. This means that the final product contains around 98% air. Most of the pentane gas is released during the manufacturing if EPS and is replaced with air. Released pentane gas will not affect the ozone layer.

EPS is suitable for disposable packaging, but is also well suited for technical products with higher density, for example bicycle helmets. EPS can be found in a variety of different colours.

Expandability (time): 50-85

Compressive strength: 0.7 kg / cm2

Flexural Strength: 2.5 kg / cm2

Standard material and Flame-retardant grade

1) Standard material (light class / middle class): with stable bubbling times and long

preservation, for packing container, panel, floating ball, arts and crafts

2) Fire resistant material: with high strength, fast forming, high foaming and oxygen

index., for building materials, civil engineering, composite plate, heat preservation

and insulation materials

3) Specification: 103, 104, 105, 106

Applications:

Electronic package,agriculture and fishery packaging vessel,thermal insulation,buoy,crafts,food and drinking container. For the production of rigid foam sheet and mouldings for applications involving exposure to pressure and moisture and so on

Characteristic:Standard grade E, uniform size,low density of block,high foaming speed, less air used when foam.

Related products

Other Products

Other Products

Other Products

Other Products

Other Products

Other Products

Other Products

Other Products